Waraporn Wichaita1, Duangporn Polpanich2 and Pramuan Tangboriboonrat1*

1Polymer Science and Technology Program, Department of Chemistry, Faculty of Science, Mahidol University, Rama 6 Road, Phyathai, Bangkok 10400, Thailand

2NANOTEC, National Science and Technology Development Agency, 111 Thailand Science Park, Phahonyothin Road, Khlong Luang, Pathum Thani 12120, Thailand

*Corresponding author: pramuan.tan@mahidol.ac.th

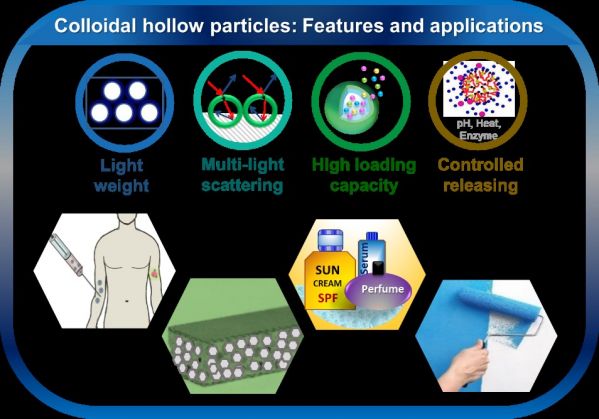

Colloidal particle having a void inside or hollow latex (HL) particle of polymers or hybrid polymer/inorganic materials endures as an important field of innovation throughout academia and industrial sector. Centered on drug delivery and coating applications, the allure of HL particles lies in the unique benefits for efficient encapsulation of active ingredients, ability to improve opacity or hiding power with low density. While the processing to meet the criteria of industrial scale is focused, developments in the preparation techniques have broadly expanded their compositions, morphologies and functionalities. This review article summarizes the recent works and leading examples on the HL particles prepared mainly from synthetic polymers. The template-based methods using sacrificial hard or soft template, self-templating, and non-sacrificial techniques to obtain both conventional and sophisticated structures are described. Our pioneering research on hollow core-shell particles via natural rubber latex seed emulsion polymerization is also reported. Various factors affecting morphologies and properties of HL particles are discussed in detail. Their applications in coatings, cosmetics, biomedicines, electronics, and others are also presented. This article serves as a guideline for the rational design of hollow polymer nano-/microparticles and encompasses the utilization for good health, wellbeing, industry and innovation. It would be beneficial for the researchers worldwide.

Acknowledgement

This work is supported by Mahidol University. The scholarship from Science Achievement Scholarship of Thailand (SAST) to W.W. is gratefully acknowledged.

References

- Ind. Eng. Chem. Res. 2019, 58, 46, 20880-20901 (DOI: 10.1021/acs.iecr.9b02330)

- Polymer 2016, 99, 324-331 (DOI: 10.1016/j.polymer.2016.07.032)