Pranee Phinyocheep

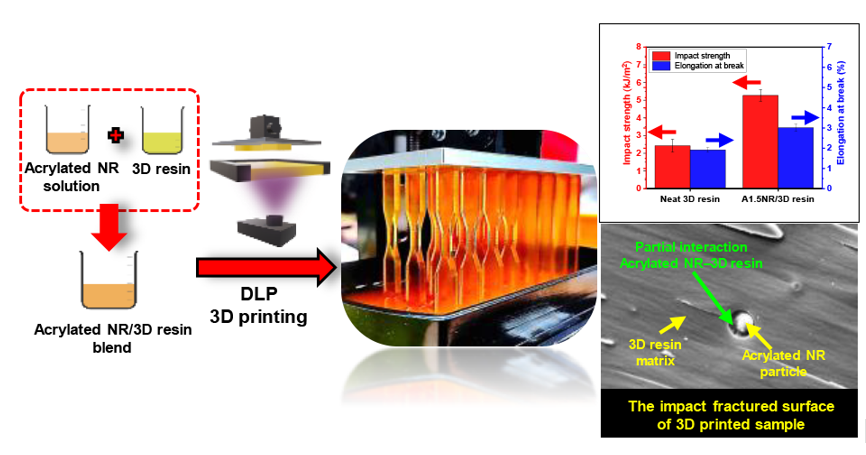

Natural rubber (NR) obtained from Hevea brasiliensis tree is one of the important economic crops in Thailand and Thailand is the world’s largest NR producer. It possesses an excellent elastic property and contains carbon-carbon double bonds, which can be chemically modified into various functional materials. In this study, it was transformed into photosensitive material containing acrylate functional groups named as acrylated natural rubber (ANR). Various acrylate contents (0.0–3.5 mol%) of ANR were prepared and then incorporated with commercial 3D resin to fabricate specimens using digital light processing. As a result, the utilization of ANR with 1.5 mol% acrylate content could provide the maximum improvement in stretchability and impact strength, approximately 155% and 221%, respectively, over using pure 3D resin. The evidence from a scanning electron microscope could be used to indicate the partial interaction between the dispersed small rubber particles and the resin matrix. Additionally, the glass-transition temperature of the 3D-printed sample shifted to a lower temperature by introducing a higher acrylate content in the ANR. Therefore, this work might offer a practical way to effectively enhance the properties of the fundamental commercial 3D resin and broaden its applications. It also makes it possible to use natural rubber as a bio-based material in light-based 3D printing.

Reference:

W. Tessanan, P. Daniel and P. Phinyocheep, Mechanical Properties’ Strengthening of Photosensitive 3D Resin in Lithography Technology Using Acrylated Natural Rubber;

Polymers 2023, 15(20), 4110