Taweechai Amornsakchai

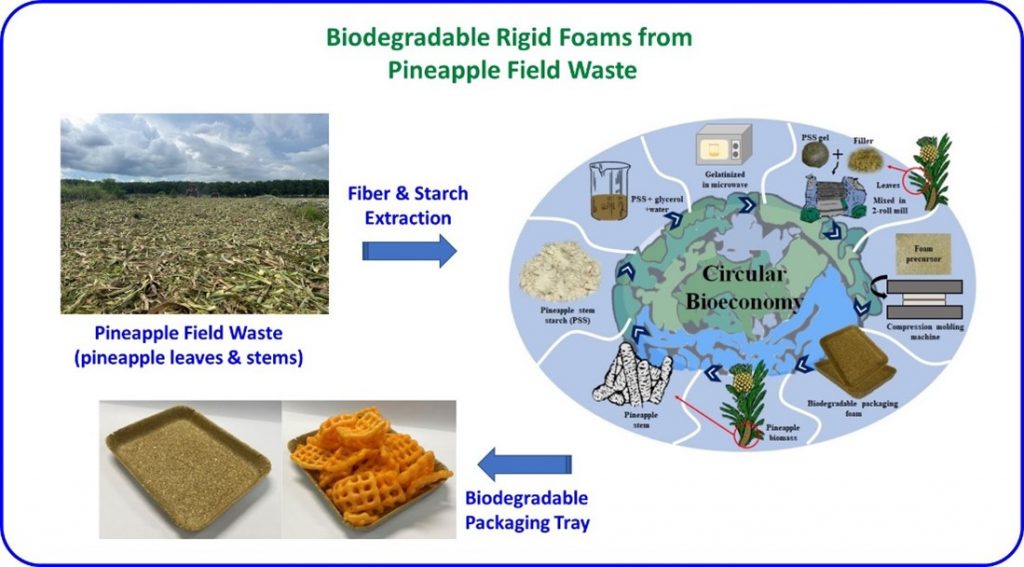

Pineapple waste materials have been used to create new types of eco-friendly rigid composite foams that are biodegradable. The foam’s base material is starch extracted from pineapple stems, which is known for its high amylose content. The filler material is made from non-fibrous cellulosic materials sourced from pineapple leaves.

Instead of the traditional method of creating a batter, this study used a unique approach. The researchers first formed a gel by combining the starch and glycerol in a household microwave oven. Then, they blended the filler material into the gel using a two-roll mill. The resulting mixture was foamed at 160 °C using a compression molding machine.

The foams had densities ranging from 0.43 to 0.51 g/cm3 and exhibited a highly amorphous structure. They could absorb 150-200% of their weight in moisture without falling apart and had an equilibrium moisture content of approximately 8-10%. The flexural strength of the foams varied between 1.5 and 4.5 MPa, depending on the filler and glycerol contents.

Biodegradability tests showed that the foams completely disintegrated into small particles within 15 days when buried in soil. To demonstrate practical use, the researchers also created an environmentally friendly single-use foam tray.

Reference: “Development of Biodegradable Rigid Foams from Pineapple Field Waste”, Namphonsane, A.; Amornsakchai, T.; Chia, C.H.; Goh, K.L.; Thanawan, S.; Wongsagonsup, R.; Smith, S.M., Polymers 2023, 15, 2895.