Taweechai Amornsakchai

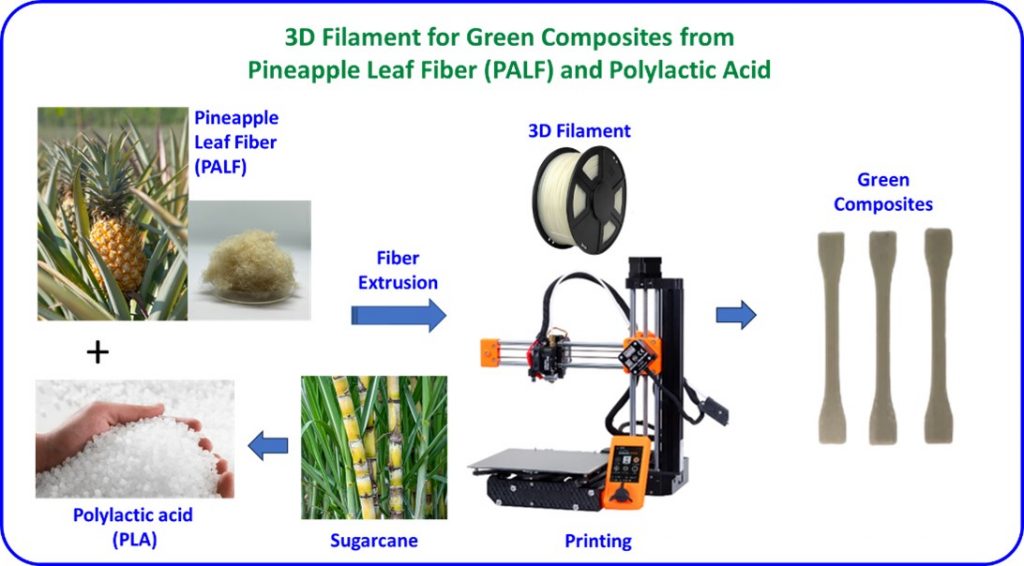

This study aimed to develop a sustainable and biodegradable composite material for 3D printing of food and medical product packaging. A novel composite was made of polylactic acid (PLA) reinforced with pineapple leaf fiber (PALF). The mechanical, crystalline, chemical bonding, and thermal characteristics of the 3D printed composite were examined. Filaments were created by mixing powdered PALF (both raw and alkali-treated) with PLA for the 3D printing process. Results showed that the composite with 3% alkali-treated PALF exhibited the highest tensile and flexural properties. Increasing the PALF content led to higher density in the composite. However, the composite blended with raw PALF demonstrated improved elongation at break compared to the alkali-treated PALF composite. Microstructural analysis revealed impurities, voids, and fiber degradation in the 3D printed composite specimens. Chemical bonding was confirmed through Fourier transform infrared spectra, while X-ray diffraction provided insights into crystalline size and crystallinity index. Thermogravimetric analysis indicated adequate thermal stability of the 3D printed composite for packaging applications.

Reference: “Comprehensive characterization of raw and treated pineapple leaf fiber/polylactic acid green composites manufactured by 3D printing technique”, Mansingh, B.B., Binoj, J.S., Tan, Z.Q., Eugene, W.W.L., Amornsakchai, T., Hassan, S.A., Goh, K.L., Polymer Composites. 43(9), 6051 (2022).