Taweechai Amornsakchai

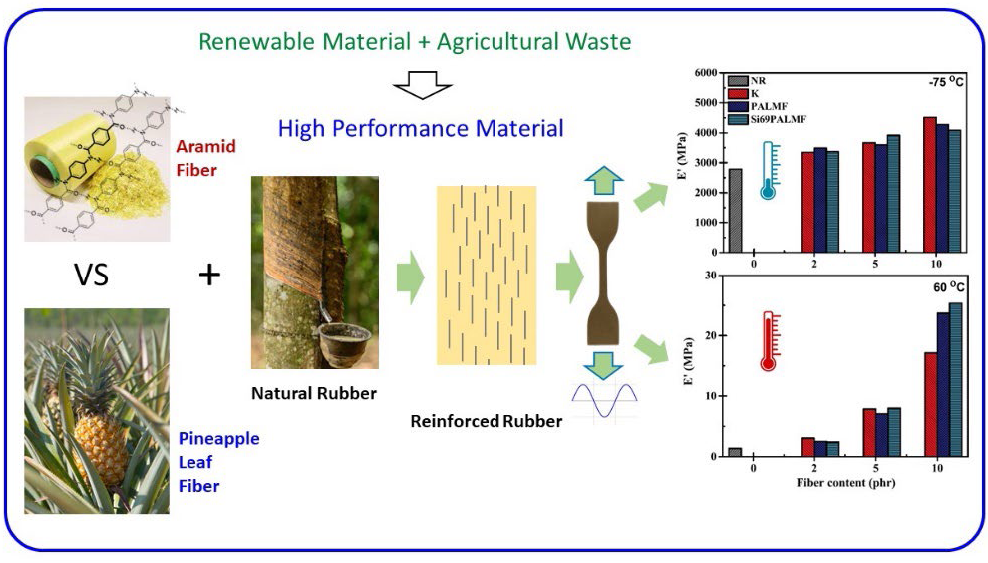

Pineapple leaf fiber (PALF) is known to have relatively high mechanical properties compared with other natural fibers and closer to that of high performance synthetic fiber such as aramid. Since PALF is derived from waste pineapple leaves, it has very low carbon footprint. In this research, PALF and aramid fiber were used to reinforce natural rubber (NR) to produce unidirectional rubber composites that resist deformation in the direction parallel to fiber alignment. Fiber content was varied from 0 to 10 parts (by weight) per hundred of rubber (phr). The composites mechanical performance was compared with that of aramid fiber reinforced NR of the same fiber content. It was found that, at very low temperature, aramid fiber performed slightly better than PALF. However, as the temperature was increased to room temperature and 60°C, PALF displayed better performance that aramid at fiber content of 10 phr. The result clearly indicates that PALF has a high potential as green and high performance reinforcement for rubber.

Reference: “Comparative study of pineapple leaf microfiber and aramid fiber reinforced natural rubbers using dynamic mechanical analysis”, Surajarusarn, B., Hajjar-Garreau, S., Schrodj, G., Mougin, K., Amornsakchai, T., Polym. Test. 82, 106289 (2020).