Taweechai Amornsakchai

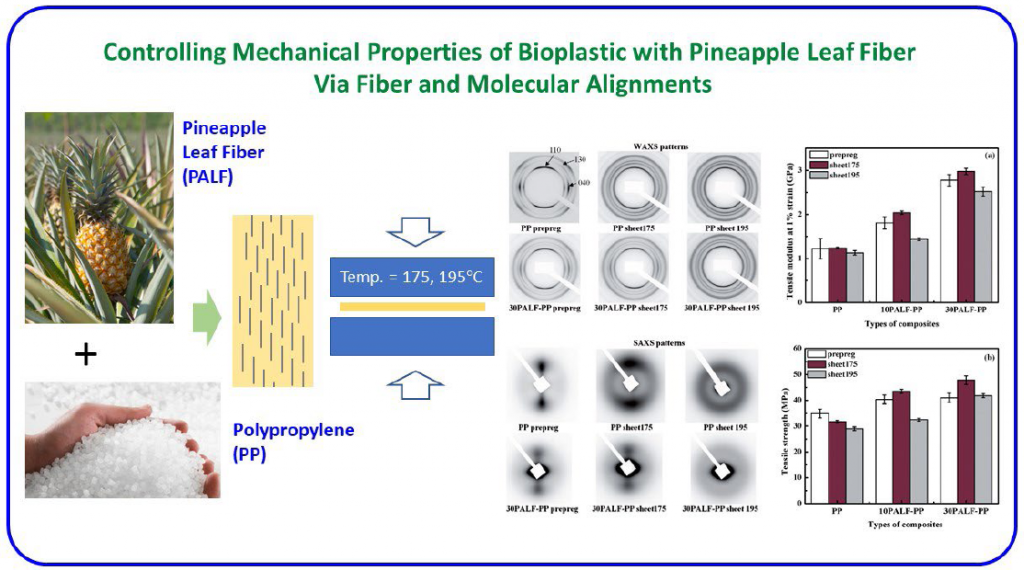

Reinforcement of polypropylene can be achieved via different techniques. Natural fibers offer many advantages in this regard. Not only that they can provide reinforcement according to mechanical model, natural fibers also influence the structural development of specific internal structure which could provide additional benefits. In this work, pineapple leaf fiber (PALF) was chosen as the reinforcement for polypropylene (PP) as it has high mechanical properties as well as very low carbon footprint. PALF -PP composites were prepared by melt mixing on a two-roll mill and taken out to form uniaxial ‘prepreg’. The ‘prepreg’ was stacked and compressed at 175 and 195 °C to form uniaxial sheets. Small and wide angle x-ray scattering patterns reveal that the crystalline orientation and stacked structure are still preserved in sheets compressed at 175 °C. However those compressed at 195 °C lose all. Composites prepared at 175 °C display greater modulus and strength. This is due to the combined effect of matrix and PALF orientation. These observations could be employed to maximize the achievable mechanical performance of the composites. It could also be extended to other polymer systems.

Reference: “Effect of Matrix Orientation and Fiber Content on the Properties of Uniaxial Pineapple Leaf Fiber – Polypropylene Composites”, Kengkhetkit, N., Amornsakchai, T., KGK-Kaut. Gummi. Kunst. 72(5), 44-50 (2020).