Taweechai Amornsakchai

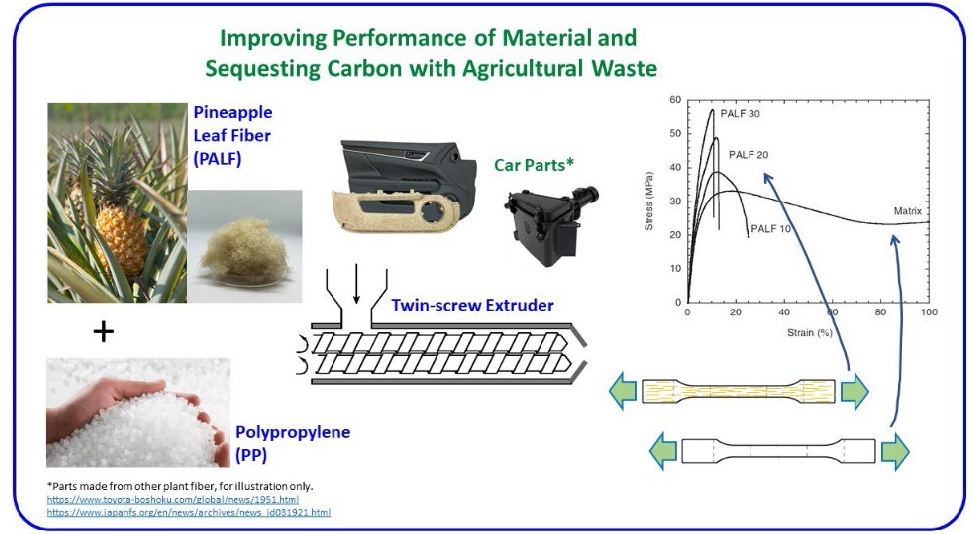

We need different kinds of materials to make things with. At the same time, we need to protect our environment for the next generations. Plastic is one of very versatile materials. Plastic can be reinforced effectively with natural fiber. With proper selection, both performance and care for the environment can be achieved. In this paper, pineapple leaf fiber (PALF) was used to prepare polypropylene-based composites by twin-screw extrusion. The objective was to evaluate the influence of the fiber content (between 10 and 30 wt%) on the rheological and mechanical properties of the composites. The rheological behavior of the composites was directly impacted by the fiber content, with a regular increase of the viscosity and the development of a melt yield stress above 20 wt% PALF. The mechanical properties showed an increase in Young’s modulus (+115% at 30 wt% PALF) and stress at break (+72% at 30 wt% PALF), proportional to the fiber content, but a sharp decrease in elongation at break (from 980% to 10% at 30 wt% PALF). These results confirm that the fiber content is the main parameter controlling the rheological and mechanical properties of the PALF/PP composites and that this fiber from agricultural waste can be considered as a good candidate for various applications of PP-based composites.

Reference: “Influence of fiber content on rheological and mechanical properties of pineapple leaf fibers-polypropylene composites prepared by twin-screw extrusion”, Berzin, F., Amornsakchai, T., Lemaitre, A., Castellani, R., Vergnes, B., Polym. Compos. 40(12), 4519-4529 (2019).