Taweechai Amornsakchai

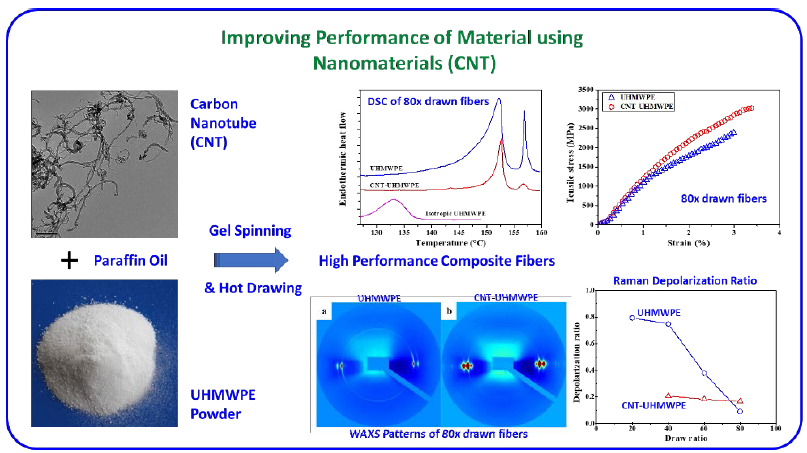

By aligning fully stretch polymer molecules, we are able to exploit the full potential of chemical bonds. This can be achieved by proper drawing or stretching of suitable polymer materials. However, stretching does not always result in fully stretched molecules but braking. Ultra high molecular weight polyethylene (UHMWPE) has similar chemical structure to that of milk bottle or carry bag but has much greater molecular weight or length. Proper alignments of its molecules lead to very strong and stiff polymer fibers. In this paper, carbon nanotube (CNT) which is known to be very strong and light was used to improve the mechanical properties of UHMWPE. Solution of UHMWPE and 5% by weight of CNT was prepared and spun into gel fiber which was then drawn to draw ratios of 20x, 40x, 60x and 80x. The presence of CNT had no effect on the maximum draw ratio achieved but was found to reduce the numbers of tiny crack formed on the fiber surface at high draw ratios. It also causes the formation of monoclinic crystal structure during drawing. The drawn fiber exhibits higher extensibility. The highest strengths obtained for CNT-UHMWPE and UHMWPE fibers were 2856 and 2315 MPa, respectively, while their respective moduli were 126 and 115 GPa.

Reference: “Preparation and Properties of High Strength Composite Fibers from UHMWPE and Carbon Nanotubes”, Achuayram, S., Amornsakchai, T., KGK-Kaut. Gummi. Kunst. 75(2), 60-65 (2022).