Pranee Phinyocheep

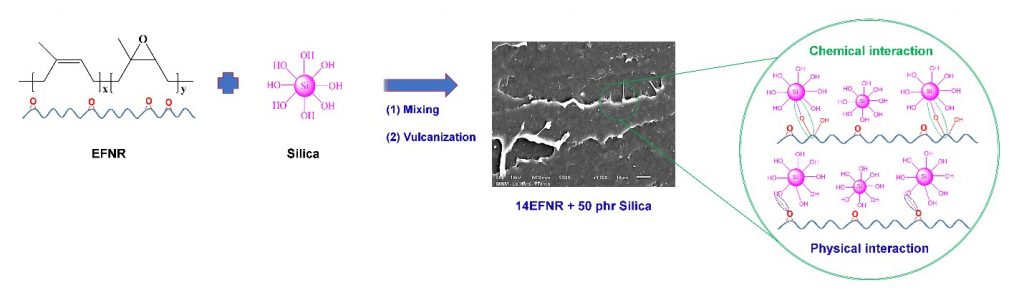

In this research, 3 different low degrees (4, 8, and 14 mole%) of epoxide functionalized natural rubber were prepared via chemical modification of natural rubber, which was then vulcanized. Each of them was mixed with silica (50 parts per hundred of rubber) without a silane coupling agent and investigated their properties. It was found that the tensile and tear properties, as well as abrasion resistance of the silica filled epoxide functionalized natural rubber vulcanizates were higher than the silica filled natural rubber vulcanizate. These properties improvements could be attributed to the interaction of the silanol groups of the silica with the epoxide groups of the modified rubber chains via chemical and physical interactions. This could be supported by the occurrence of tear parts from the morphology investigation of the tensile fractured surface of the modified rubber vulcanizates using a scanning electron microscope. The presence of silicon elements in the rubber matrix was evidenced by scanning electron microscopy and energy dispersive X-Ray spectrometer. Moreover, the silica filled epoxide functionalized natural rubber having 14 mole% epoxide content without a silane coupling agent exhibited low abrasion loss, low heat build-up and enhancement in loss tangent at 0ºC, hence improved wet skid resistance, compared to the silica filled natural rubber without a silane coupling agent. This work demonstrated that the prepared low degree of epoxide functionalized natural rubber could be potentially applied to the tire tread rubber application without the use of a silane coupling agent.

Reference: P. Nuinu, C. Sirisinha, K. Suchiva, P. Daniel, P. Phinyocheep; Journal of Materials Research and Technology 2023, 24, 2155-2168