Pranee Phinyocheep

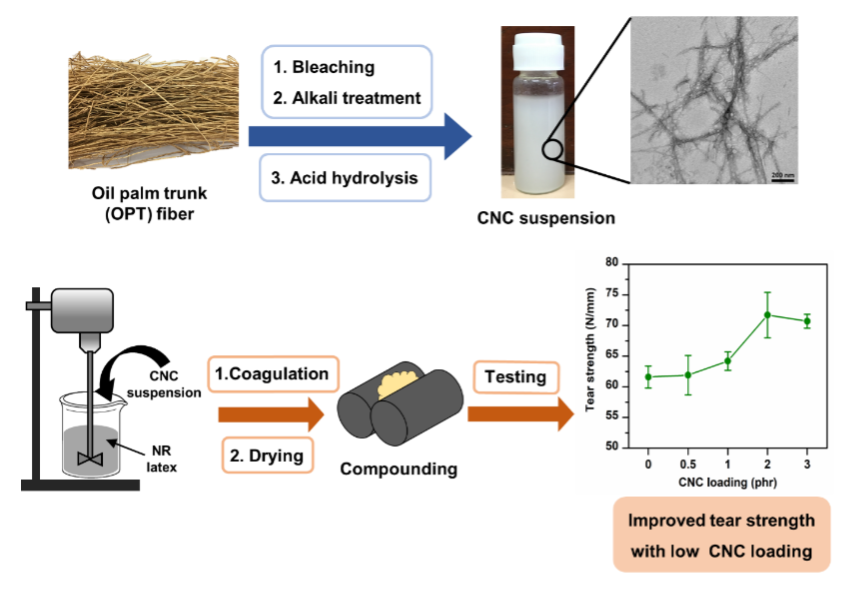

There have been numerous reports of cellulose nanocrystals (CNC) being used as a reinforcing filler in polymeric materials. It can be prepared from agricultural waste or crop leftovers, both of which are readily available and inexpensive. In this work, CNC from oil palm trunk (OPT) biomass was isolated without dialysis purification utilizing a straightforward and time-saving procedure that involves bleaching, alkali treatment, sulfuric acid hydrolysis, washing, and neutralization. The removal of the non-cellulosic components from the starting material was confirmed using Fourier transform infrared spectroscopy. The morphology of the as-prepared CNC, which had an average diameter of 5.05 nm and an estimated length of 100–400 nm, was confirmed by transmission electron microscopy (TEM). X-ray diffraction analysis reveals that the CNC is 69.6 percent crystalline. Natural rubber (NR) nanocomposites reinforced with CNC were prepared by mixing NR latex and CNC suspension. In this article, it was reported for the first time on the curing characteristics, mechanical and thermal properties of rubber composites filled with low CNC loading (0.5 – 3 phr) derived from OPT. It’s interesting to observe that after just 2 and 3 phr of CNC loading, the NR/CNC nanocomposites’ tear strength increases by 16.2 percent and 14.8 percent, respectively, over the pure NR. This discovery highlighted both the value of using a tiny amount of CNC as a reinforcing agent for NR, particularly for the improved tear strength of the rubber nanocomposites, and the simple and effective extraction process of the CNC from OPT biomass.

Reference:

N. Koeipudsa, R. Chanthateyanonth, P. Daniel and P. Phinyocheep; Journal of Polymer Research, 2022, 29(9), 403