Due to the increasing environmental awareness and the wish to reduce the crude oil dependency, PLA as a bio-based and biodegradable plastic gradually becomes more common on the market in various technical applications, it is imperative to study how this polymer can be effectively recycled.

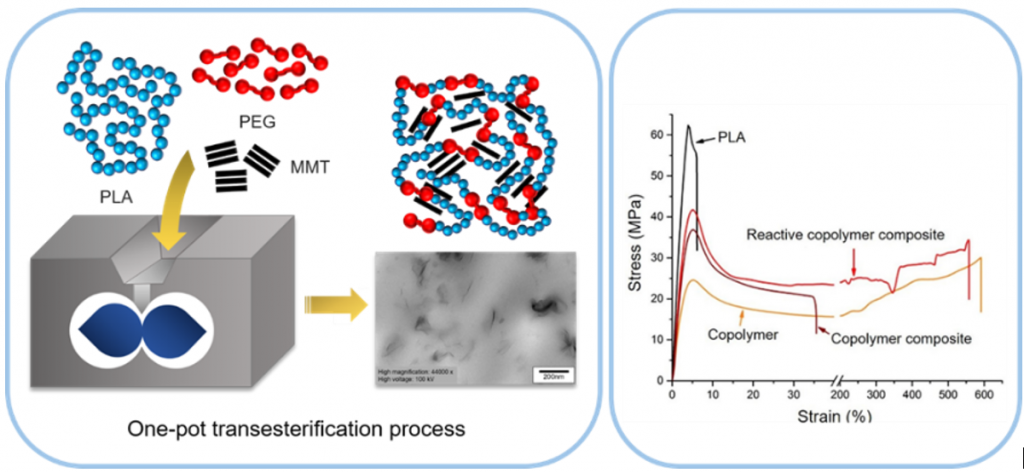

In this work, we present a one-pot melt process for turning PLA post-consumer waste into a biodegradable block copolymer and copolymer composite of high strength and ductility. We used PLA disposable dome lid for cold drinking cups which is the most common application of PLA in the household area as a starting material. The process was conducted in a melt-mixer through a transesterification reaction of PLA with poly(ethylene glycol) (PEG) as soft component and clay as reinforcement.

The products with a broadened range of properties can be designed. With good mechanical performance, the products from this process would serve industrial markets including disposable packaging and agricultural films. In addition, a one-pot reactive melt process for PLA developed in this work has many advantages that would make it applicable for industrial operations. The process is easy to execute and economical to operate, as it can be done in the melt without solvent, thus providing a low environmental impact.

This research project was funded by the National Research Council of Thailand (NRCT) under the Research University Network Initiative. Associated SDG goals are Industry, innovation and infrastructure (9), and Responsible consumption and production (12)

For more details:

Kalyanee Sirisinha, Supa Wirasate, Chakrit Sirisinha, Noppasorn Wattanakrai, One-Pot Reactive Melt Recycling of PLA Post-Consumer Waste for the Production of Block Copolymer Nanocomposites of High Strength and Ductility. Polymers 2022, 14, 3642. https://doi.org/10.3390/polym14173642