Pranee Phinyocheep

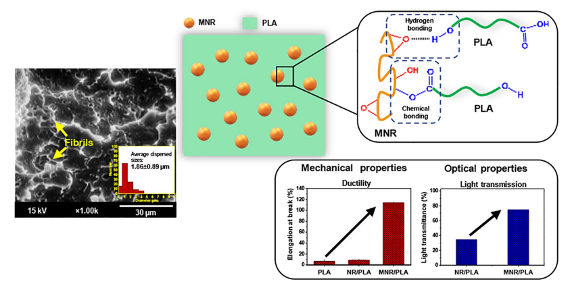

The toughening modification of PLA was successfully performed by incorporating modified natural rubber (MNR). The MNR was obtained from a chemical modification of natural rubber (NR) in a latex system through a two-step procedure; hydrogenation followed by an epoxidation reaction. Different amounts of NR and MNR were mixed with PLA by a physical melt-blending procedure. As a result, blending MNR (5% by weight) with PLA could efficiently strengthen fracture resistance (18.89 kJ/m2) and stretchability (113.79%), approximately fivefold and 16-fold, respectively, compared to the neat PLA (3.58 kJ/m2 impact strength and 7.08% elongation-at-break). In comparison, impact strength (7.21 kJ/m2 ) and elongation-at-break (8.64%) of NR/ PLA were found at the same weight ratio. The high toughening efficiency of MNR for PLA could be explained by the good compatibility of the two phases. The impact-fractured surface of the blend showed fine rubber particles and stretched rubber fibrils in the scanning electron microscope (SEM) image. Furthermore, the optical properties in terms of light transmission of the MNR/PLA blend displayed higher transparency (74.62%) than the unmodified NR/PLA blend (34.34%). The obtained results suggest that the developed MNR will offer a potential application as a high-impact modifier for PLA.

Reference: Wasan Tessanan, and Pranee Phinyocheep. “Toughening modification of poly (lactic acid) using modified natural rubber.” Iranian Polymer Journal 2022, 31(4), 455-469