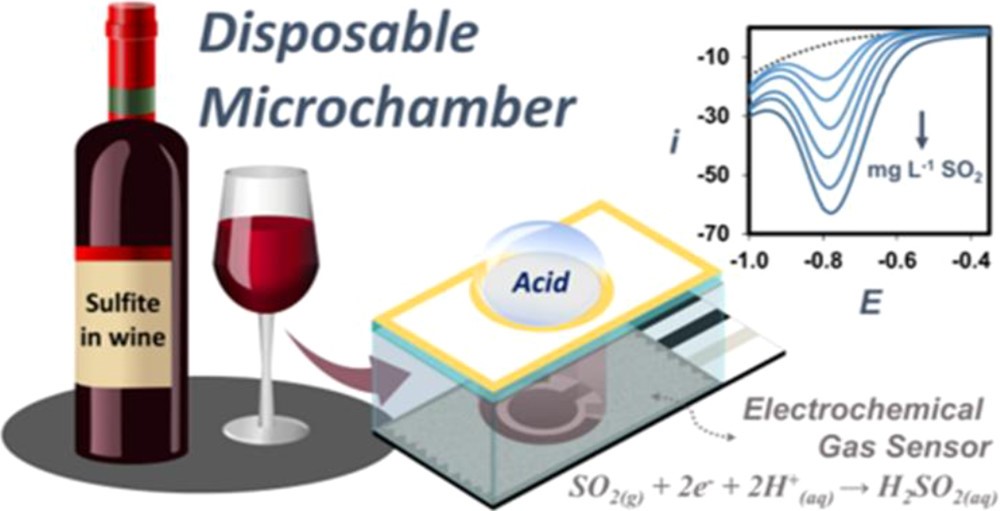

This work presents a fully disposable microchamber for gas generation of a sample solution. The microchamber consists of a cylindrical well-reactor and a paper-based microfluidic lid (μFluidic lid), which also serves as the reagent loading and dispensing unit. The base of the reactor consists of a hydrophobic membrane covering an in-house graphene electrochemical gas sensor. Fabrication of the gas sensor and the three-layer μFluidic lid is described. The μFluidic lid is designed to provide a steady addition of the acid reagent into the sample solution instead of liquid drops from a disposable syringe. There are three steps in the procedure: (i) acidification of the sample in the reactor to generate SO2 gas by the slow dispensing of the acid reagent from the μFluidic lid, (ii) diffusion of the liberated SO2 gas through the hydrophobic membrane at the base of the reactor, and (iii) in situ detection of SO2 by cathodic reduction at the graphene electrode. The device was demonstrated for quantitation of the sulfite preservative in wine without heating or stirring. The selectivity of the analysis is ensured by the combination of the gas-diffusion membrane and the selectivity of the electrochemical sensor. The linear working range is 2–60 mg L–1 SO2, with a limit of detection (3SD of intercept/slope) of 1.5 mg L–1 SO2. This in situ method has the shortest analysis time (8 min per sample) among all voltammetric methods that detect SO2(g) via membrane gas diffusion.

Reference: Prasertying, P.; Ninlapath, T.; Jantawong, N.; Wongpakdee, T.; Sonsa-ard, T.; Uraisin, K.; Saetear, P.; Wilairat, P.; Nacapricha, D., Disposable Microchamber with a Microfluidic Paper-Based Lid for Generation and Membrane Separation of SO2 Gas Employing an In Situ Electrochemical Gas Sensor for Quantifying Sulfite in Wine. Analytical Chemistry 2022, 94 (22), 7892-7900.