Noirahaeng N, Uraisin K, Wattanasin P, Saetear P.

Laminated paper-based analytical device (LPAD) is categorized as one in a group of microfluidic paper-based analytical device (mPAD). A cutting plotter equipped with a craft cutter was originally employed for cutting a filter/chromatography paper to obtain paper strips, depending on the design and analytical procedure. The paper strips were then laminated with a cover sheet and a bottom sheet by a thermal laminator. The laminated cover sheet had a cutout pattern the same as the paper strip with a slightly smaller dimension, resulting in accessibility for the reagent and sample dispensing on the paper strip. The laminated plain bottom sheet was used as mechanical support as received.

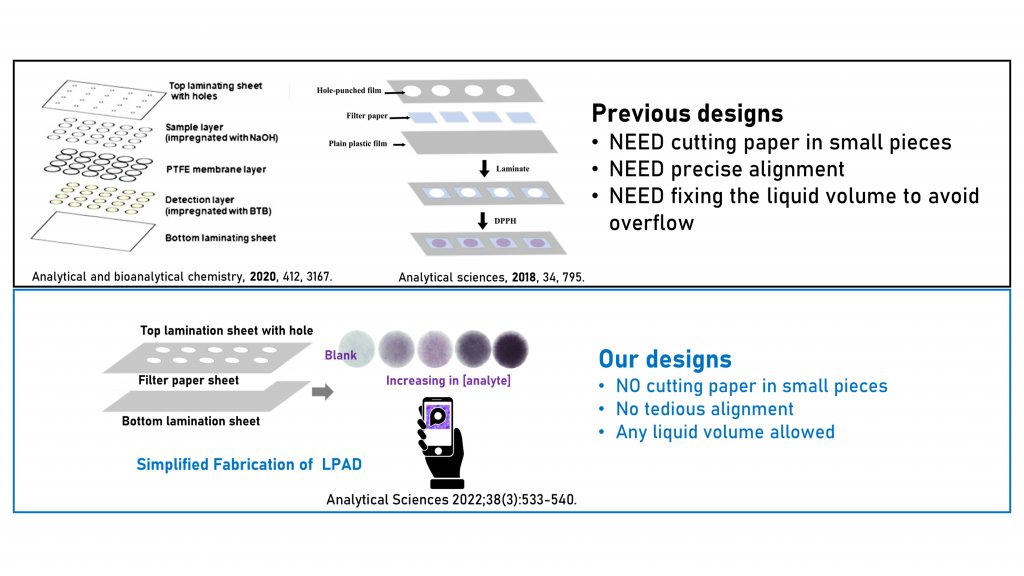

Later on, the lamination process was adopted to fabricate the mPADs; even later work was not used the terms of LPAD. The paper platform was not a strip, but was designed to cut the paper as circular discs and square discs by using a hole puncher and an office cutter/scissors, respectively. For circular disc design, multilayer alignment, including the top laminating sheet, circular paper discs and hydrophobic membrane discs, was proposed for the analysis of ammonia based on gas-diffusion. The top sheet of the laminating pouch was perforated with circular holes of 3-fold smaller diameter than the circular disc, so as to ensure that punched holes were aligned on the circular paper disc. However, precise alignment for multilayer assembly is crucial. A square disc was later designed to reduce the time-consuming alignment by a placing square disc with arranging under the circular hole-punched laminating sheet. With the same concept, punched holes were slightly smaller than the square disc. This design was applied to analyze the antioxidant activity.

From our point of view, cutting small pieces of paper strips/discs is simple for fabricating an LPAD. However, the precise alignment of the paper strips/discs to the hole-punched laminating sheet is still required, and is time-consuming. In this work, we therefore simplified for the first time the way to fabricate the LPAD by inserting a piece of rectangular filter paper (9 ´ 3 cm2) between the cover laminating sheet with perforated holes and the bottom laminating sheet. In this way, the precise alignment of the paper strip/disc, can be avoided, resulting in a simpler fabrication of LPAD. Our simplified LPAD was demonstrated to determine salicylic acid, SA (as beta hydroxy acid, BHA) in pharmaceutical products. Ferric reagent was employed to chemically react with salicylic acid, forming a violet complex of [Fe3+-(SA)2]+. A smartphone was used to obtained images of a violet complex on the detection zone of the LPAD. We also simplified the step of image analysis by using a free color-palette mobile application, named Palette Cam, instead of using an ImageJ processing software. The Palette Cam app was manipulated for simplified analyzing in the RGB (red, green, blue) color mode. The color intensity obtained from the Palette Cam is converted into a color ratio as log I0/I (I0, the intensity of blank; I, intensity of standard or sample). Our proposed fabrication and detection methods on the LPAD were evaluated and validated by a comparative spectrophotometric method.

Visit a full article

https://www.jstage.jst.go.jp/article/analsci/advpub/0/advpub_21P231/_article

https://link.springer.com/article/10.2116/analsci.21P231