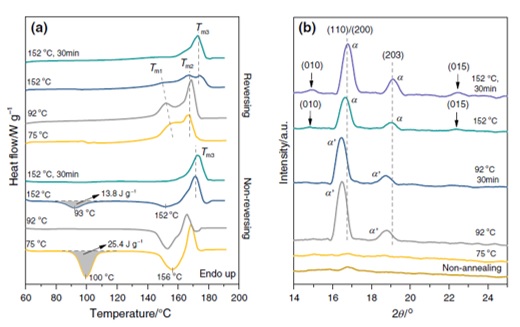

The demand for poly(lactic acid) (PLA) and PLA-based blends has been continuously increasing in new applications and products. These materials are attractive because they offer a number of additional advantages compared to conventional fossil-based plastics such as a reduced carbon footprint and low waste management problems. PLA possesses complex crystallization behaviors. Crystallization of PLA can be controlled by thermal treatment. In the study, the complex crystallization-melting behaviors of the molded PLA/PBS products after subjecting to post-process thermal treatment are investigated by TMDSC and WAXD measurement. Post-process annealing of the molded parts is necessary for some industrial applications for enhancing the mechanical properties, heat resistance, and dimensional stability at high temperatures. Therefore, understanding polymer crystallization upon annealing is highly beneficial to the polymer industry for developing the products of the required performance.

This research project was partially funded by the National Research Council of Thailand (NRCT) under the Research University Network Initiative. Associated SDG goals are Industry, innovation and infrastructure (9), and Responsible consumption and production (12).

Reference: Todsapol Kajornprai and Kalyanee Sirisinha*, Effect of thermal annealing on crystal evolution and multiple melting behaviors of molded poly(L-lactic acid) and poly(butylene succinate) blends upon heating investigated by TMDSC, Journal of Thermal Analysis and Calorimetry, 2021, doi.org/10.1007/s10973-021-10629-1.