Project Title: Development of a solvent-free reactive melt-processing method for the production of biodegradable PLA-based copolymers with high ductility and toughness

Kalyanee Sirisinha, Polymer Science and Technology, Faculty of Science

Rationale: Bioplastics have gained tremendous attention, due to the increasing environmental concerns and the decreasing petroleum resources. Among them, polylactic acid (PLA) with its excellent transparency, and high mechanical strength, has been involved in varieties of industries such as packaging and automotive industries. Various kinds of methods have been used to bring down the cost and enhance the ductility of PLA. Copolymerization of PLA with soften materials are the commonly used methods. Most of PLA-based copolymers are synthesized via ring-opening polymerization of lactide monomer, which possesses several drawbacks including long production time, complicated step, and requirement of purification and solvent evaporation, leading to high investment cost.

Research goal: This project has the aim to find effective approach for the production of PLA-based copolymers via reactive melt compounding method. Instead of using conventional ring-opening polymerization of lactide, transesterification reaction was used in which commercial grade PLA or even recycled PLA could be utilized as starting material.

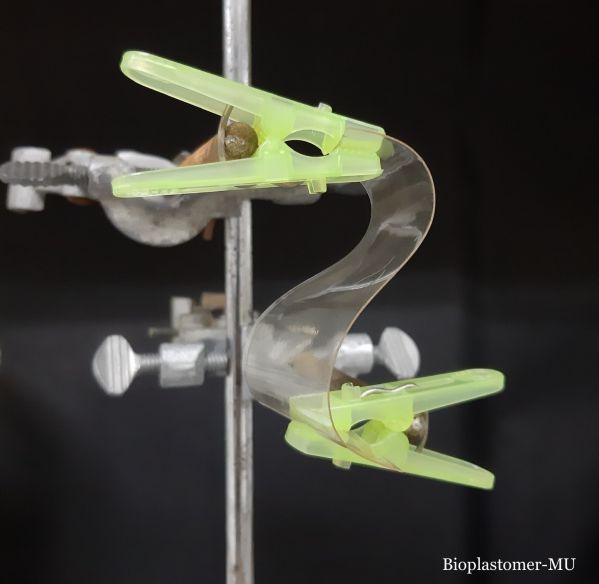

Findings: The project generates technological advancement in the production of PLA-based block copolymers with outstanding mechanical performance using simple melt processing technique. The reaction between PLA and polyethylene glycol (PEG) occurs very fast in a melt mixer. No solvent for the polymers is needed in the process and this makes the process more environmentally friendly. By optimizing the conditions, the copolymer products possessing super-ductile behavior are obtained, showing a tensile elongation of 500% or hundred times higher than that of starting PLA.

Potential Use: The copolymers of this work have high potential to be substitutions of some petroleum-based plastics (such as PE) or to be used as toughness enhancer for PLA blends and composites. The in-depth understanding of the relationship between microstructure and property allows the design of copolymer with high-strain shape memory behaviors that could be used in medical applications.

Research Funding and Networking: This project is supported by the National Research Council of Thailand (NRCT) under the Research University Network (RUN) Initiative. We are currently working together with academic partners (KU, PSU) in an effort to expand the use of copolymer products from this project and develop technological knowledge for the sustainable and bio-industry of the future.